Top 10 Benefits of Precast Concrete for Modern Construction Projects

In the realm of modern construction, precast concrete has emerged as a game-changing material that offers an array of advantages for building projects of all sizes. This innovative approach to construction involves casting concrete components in a controlled environment before transporting them to the construction site for assembly. This technique not only enhances the efficiency of the building process but also contributes to a higher standard of quality and durability in construction.

One of the standout benefits of precast concrete is its ability to streamline construction timelines. By allowing for simultaneous site preparation and casting processes, precast concrete significantly reduces the overall project duration. Furthermore, its inherent properties, such as strength and resistance to harsh weather conditions, make it an ideal choice for various applications, from residential homes to large-scale commercial buildings. As we delve into the top ten benefits of precast concrete, it becomes evident that its versatility and performance capabilities position it as a cornerstone of modern construction practices. Whether it’s the flexibility in design or the sustainability aspects of precast concrete, this innovative material is revolutionizing how we think about building the structures of tomorrow.

Advantages of Precast Concrete in Construction Efficiency

Precast concrete has revolutionized modern construction by significantly enhancing efficiency in various stages of building projects. One of the foremost advantages of precast concrete is its ability to streamline the construction timeline. By manufacturing components off-site, workers can overlap different phases of the project, allowing for simultaneous site preparation and structural work. This reduces the overall duration of construction, leading to faster project completion and lower labor costs.

Additionally, precast concrete components are fabricated in controlled environments, ensuring superior quality and consistency. This minimizes the risks associated with weather disruptions and onsite errors, allowing for more predictable construction schedules. The precision of precast elements leads to less waste and improved sustainability, as components are designed for optimal resource usage. Overall, the efficiency gains delivered by precast concrete not only enhance project speed but also improve the overall quality and cost-effectiveness of modern construction endeavors.

Top 10 Benefits of Precast Concrete for Modern Construction Projects

| Benefit | Description |

|---|---|

| Time Efficiency | Precast concrete can be manufactured off-site while site preparation is ongoing, significantly reducing project timelines. |

| Cost-effectiveness | Lower labor and material costs can be achieved due to speed and efficiency, often resulting in overall budget savings. |

| Quality Control | Precast concrete is produced in controlled environments, ensuring uniform quality and reducing defects. |

| Design Flexibility | Available in various shapes and sizes, allowing for versatile architectural designs. |

| Sustainability | Precast concrete can be made from recycled materials and has a long lifespan, contributing to sustainable construction practices. |

| Durability | Resistant to weather, fire, and pests, enhancing the longevity of structures. |

| Reduced Site Disruption | Since most work is done off-site, there is less noise and disturbance during construction. |

| Safety | With fewer workers on-site and less risk of weather-related issues, the overall safety during construction is improved. |

| Energy Efficiency | Precast concrete systems can incorporate insulating materials, improving energy efficiency in buildings. |

| Speed of Installation | Precast elements can be quickly and easily assembled on-site, accelerating the construction process. |

Cost-Effectiveness of Precast Concrete Solutions

Precast concrete solutions have gained significant popularity due to their cost-effectiveness in modern construction projects. One of the primary advantages is the reduction in labor costs. Since precast elements are manufactured in a controlled environment, the need for extensive on-site labor is minimized. This leads to faster project completion times, allowing developers to save on costs associated with prolonged construction periods. Additionally, efficiency in the production process results in consistent quality, reducing the likelihood of expensive rework and delays caused by on-site issues.

Another aspect of cost-effectiveness lies in the materials used in precast concrete. By optimizing the production and utilizing advanced techniques, waste is significantly reduced. This not only decreases raw material costs but also aligns with sustainable practices, which are increasingly valued in contemporary construction. Furthermore, the durability of precast concrete elements leads to lower maintenance costs over time, making it an economically sound choice for investors looking for long-lasting construction solutions. Ultimately, these financial advantages make precast concrete a compelling option for modern building projects, enhancing both affordability and efficiency.

Durability and Longevity of Precast Concrete Structures

Precast concrete is increasingly recognized for its exceptional durability and longevity, making it a preferred choice in modern construction projects. One of the primary advantages of precast concrete is its ability to withstand harsh environmental conditions. Unlike traditional cast-in-place methods, precast elements are manufactured in controlled environments, ensuring better quality control and reducing the likelihood of defects caused by weather variations. This results in structures that not only resist erosion, corrosion, and extreme temperatures but also maintain their aesthetic appeal over time.

Moreover, the lifespan of precast concrete structures significantly outpaces that of many conventional building materials. The inherent properties of precast concrete, such as its high compressive strength and resistance to fire and water damage, contribute to a reduced need for repairs and maintenance. Consequently, this leads to lower lifecycle costs for building owners and enhanced safety for occupants. As modern construction increasingly emphasizes sustainability and long-term efficiency, the durability of precast concrete positions it as a vital material in creating resilient infrastructures that can endure the test of time.

Design Flexibility and Aesthetic Options with Precast Concrete

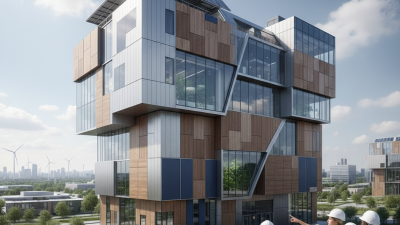

Precast concrete offers unparalleled design flexibility and aesthetic options that cater to the demands of modern construction projects. One of the standout features of precast concrete is its ability to be molded into a variety of shapes and sizes. This adaptability allows architects and designers to push the boundaries of creativity, incorporating unique textures, patterns, and colors that elevate the overall aesthetic of a structure. Whether it's for residential buildings, commercial spaces, or public infrastructure, precast concrete can be tailored to fit specific design visions, marrying form and function seamlessly.

Furthermore, precast concrete elements can mimic traditional materials such as stone, brick, or wood, providing an elegant finish without compromising durability. The use of advanced manufacturing techniques enables precision in design, which results in high-quality finishes and consistent appearances across different elements. This versatility not only enhances the building's visual appeal but also allows for innovative designs that can be realized quickly, facilitating more efficient construction timelines. As a result, precast concrete stands out as an excellent choice for modern architects seeking to create visually striking and structurally sound projects.

Sustainability Benefits of Using Precast Concrete in Construction Projects

Precast concrete has emerged as a sustainable choice in modern construction, offering various environmental advantages. Firstly, it significantly reduces waste during the construction process. Since precast components are manufactured in a controlled environment, excess material can be minimized, promoting efficient resource use. This approach not only conserves raw materials but also lessens the environmental impact associated with manufacturing processes.

Moreover, precast concrete elements can enhance energy efficiency in buildings. By integrating insulation into precast panels, they help maintain optimal indoor temperatures, reducing the need for heating and cooling systems. This contributes to lower energy consumption, which is vital in the fight against climate change.

**Tips:** When utilizing precast concrete in your next construction project, consider the design stages carefully to maximize material efficiency. Collaborating with a precast manufacturer early in the design process can also lead to innovative solutions that further enhance sustainability. Additionally, be mindful of selecting low-carbon materials and optimizing transportation logistics to minimize your overall carbon footprint.

Related Posts

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability

-

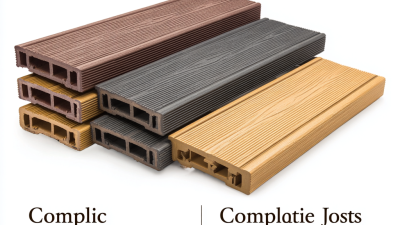

2025 Top Composite Deck Trends and Ideas for Your Outdoor Space

-

Top Reasons to Choose Composite Decking for Your 2025 Outdoor Projects

-

What are Panel Systems? Benefits, Types, and Uses Explained!

-

2025 Top 10 Panel Installation Trends You Need to Know for Your Home

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance