How to Choose the Right Metal Framing Systems for Your Construction Project

Choosing the right metal framing systems for your construction project is a vital decision that can significantly impact the overall efficiency, durability, and cost-effectiveness of your build. Metal framing systems have gained popularity in recent years due to their lightweight nature, strength, and resistance to various environmental factors, making them an ideal choice for a wide range of applications. Understanding the unique characteristics of different metal framing systems is crucial for project managers and builders aiming to optimize their construction processes.

When evaluating metal framing systems, several factors come into play, including the type of metal, structural requirements, and the specific environmental conditions of the site. Each system offers distinct advantages and drawbacks, making it essential to assess your project's needs carefully. This decision-making process involves not just considering the material properties but also understanding how these systems will integrate with other construction elements and support the overall architectural vision. By taking a strategic approach to selecting metal framing systems, you can ensure that your project meets safety standards while also achieving aesthetic and functional goals.

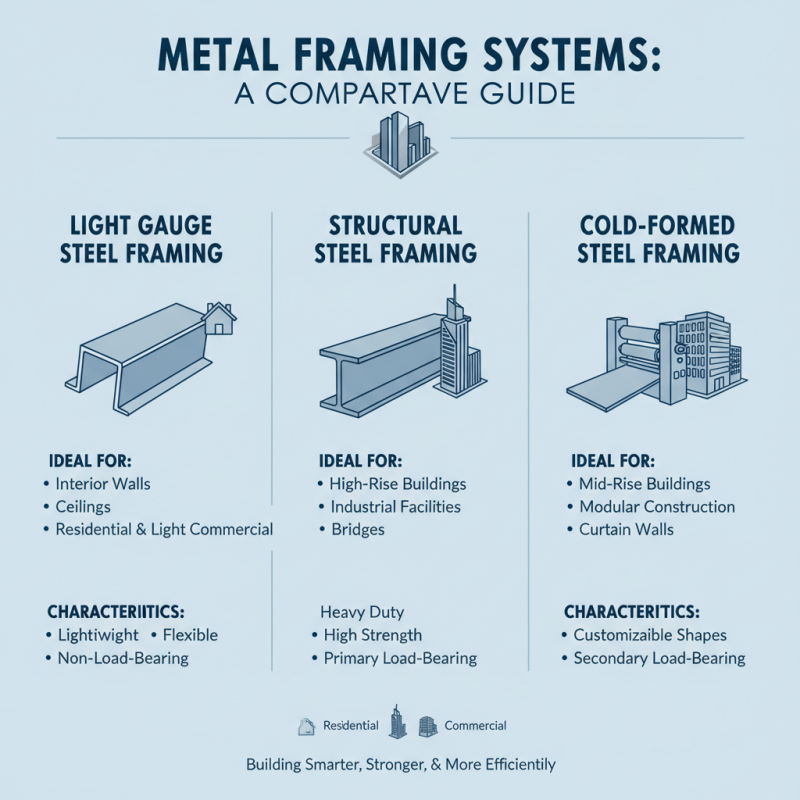

Understanding Different Types of Metal Framing Systems Available

When it comes to metal framing systems, understanding the different types available is crucial for any construction project. The most common types include light gauge steel framing, structural steel framing, and cold-formed steel framing. Light gauge steel framing is ideal for interior walls and ceilings due to its lightweight and flexibility. This system is typically used in residential and some commercial applications where low load-bearing walls are needed.

On the other hand, structural steel framing is designed for larger buildings and heavy-duty applications. It consists of steel columns, beams, and braces that provide strong support for multi-story structures. This type of framing is known for its durability and ability to withstand severe weather conditions, making it suitable for skyscrapers and industrial buildings. Cold-formed steel framing, similar to light gauge, is also lightweight but frequently used in non-structural applications such as interior partitions. This method is often chosen for its ease of installation and cost-effectiveness, making it a popular choice for modern construction projects. Each type of metal framing system has its own merits and is suited for specific needs, emphasizing the importance of selecting the right system for your project's goals.

Evaluating Project Requirements and Load-Bearing Needs

When embarking on a construction project, it is crucial to thoroughly evaluate project requirements and load-bearing needs before choosing a metal framing system. According to a report by the American Iron and Steel Institute, approximately 74% of construction professionals have identified load-bearing capacity as a primary consideration when selecting framing systems. Understanding the specific loads that your structure will endure—such as dead loads from the framing itself and live loads from occupancy—is essential for ensuring safety and structural integrity. Each project may present unique demands based on factors like building height, span lengths, and environmental influences such as wind or seismic activity.

Furthermore, the National Council of Structural Engineering Associations emphasizes the importance of adhering to local building codes and standards, which often dictate minimum load requirements based on the intended use of the building. For instance, commercial buildings typically have different loading criteria compared to residential structures. A strategic approach involves consulting with structural engineers to assess these load requirements accurately, allowing for the selection of framing systems that offer optimal performance and durability. By aligning the choice of metal framing with the specific load-bearing needs of the project, builders can significantly reduce the risk of structural failures and ensure compliance with regulatory standards.

Comparing Cost-Effectiveness of Various Metal Framing Options

When selecting metal framing systems for your construction project, considering cost-effectiveness is crucial. Research from the Steel Framing Alliance indicates that metal framing can reduce material costs by approximately 20% compared to traditional wood framing, especially for larger projects. The upfront investment in metal materials might be higher, but their durability and lower maintenance costs can lead to significant long-term savings. Additionally, metal framing systems are less susceptible to issues like warping, termites, and decay, which further contributes to overall lifecycle cost reductions.

Tips: When evaluating different metal framing options, consider the total cost of ownership rather than just the upfront costs. This includes maintenance, lifespan, and potential energy efficiency savings.

Another factor that impacts cost-effectiveness is the ease of installation. A study conducted by the National Association of Home Builders suggests that skilled labor is often necessary for metal framing, which can increase labor costs. However, the speed of installation can result in shorter project timelines, translating to savings in labor expenses overall. Alternatives such as pre-fabricated metal framing systems can streamline the process and reduce both labor and material waste.

Tips: Exploring prefabrication could not only lower labor costs but also enhance safety on the construction site, as fewer modifications and manual handling are required once on-site.

Assessing Environmental Impact and Sustainability Considerations

When selecting the right metal framing systems for your construction project, it’s essential to consider the environmental impact and sustainability aspects. Metal framing, known for its durability and strength, also offers various environmental benefits when chosen wisely. Opting for recycled metal can significantly reduce the carbon footprint of your project, as recycling metal uses a fraction of the energy compared to producing new metal. Additionally, selecting systems that are designed for longevity helps minimize waste and further supports sustainability goals.

**Tips:** Always check for certifications that indicate a product meets specific environmental standards. Look for framing systems made from galvanized steel or aluminum, as they often have a higher percentage of recycled content and are less likely to corrode, resulting in a longer lifespan.

Another crucial factor is the energy efficiency of your framing choice. Lighter systems can reduce transportation impacts while enhancing the overall thermal performance of the structure. Incorporating insulation into your metal framing design can not only improve energy efficiency but also lead to cost savings over time.

**Tips:** Consider integrating sustainable design practices in your project by consulting with engineers who specialize in green construction. They can recommend framing solutions that optimize energy efficiency without compromising structural integrity.

Environmental Impact of Different Metal Framing Systems

Selecting the Right Contractor and Installation Techniques for Metal Frames

When selecting the right contractor and installation techniques for metal framing systems, it's crucial to prioritize experience and expertise. According to a recent report from the Metal Framing Association, projects that utilized contractors with specialized knowledge in metal framing saw a 30% reduction in installation time and a 20% decrease in material waste. This underscores the importance of choosing professionals who understand the nuances of metal framing, such as load distribution, material properties, and local building codes. Additionally, contractors familiar with the latest innovations in installation technology can enhance efficiency and ensure compliance with safety standards.

Installation techniques also play a vital role in the overall success of a construction project. The National Institute of Building Sciences estimates that improper installation of metal framing can lead to structural failures and costly repairs, which may reach up to 10% of the project budget. Therefore, employing modern practices such as prefabrication can significantly streamline the assembly process. When metal frames are pre-assembled off-site, the environmental impact is reduced, and construction timelines can be accelerated. It is essential to collaborate closely with contractors who employ these advanced techniques, ensuring a durable and cost-effective outcome for your construction endeavor.

Related Posts

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability

-

Why Cold Formed Metal Framing is the Future of Sustainable Construction Solutions

-

2025 Top 10 Innovative Steel Metal Products Redefining Industry Standards

-

How to Successfully Install Solar Panels: A Step-by-Step Guide

-

2025 Top Composite Deck Trends and Ideas for Your Outdoor Space