Ultimate Guide to Choosing the Right Metal Panel for Your Project

When it comes to choosing materials for construction and design, metal panels have emerged as a popular choice due to their durability, aesthetic appeal, and versatility. According to a recent report by the Metal Construction Association, the metal panel market is projected to reach $8.7 billion by 2024, driven by increasing demand in commercial, industrial, and residential sectors. As architects and builders seek innovative ways to enhance energy efficiency and sustainability, metal panels offer solutions that can significantly contribute to a project's overall performance.

Selecting the right metal panel for your project is crucial not only for aesthetic purposes but also for ensuring structural integrity and longevity. Research from the American Institute of Steel Construction indicates that metal panels can reduce maintenance costs by up to 30% compared to traditional building materials, making them a wise investment for both short-term and long-term projects. The growing trend towards eco-friendly construction further supports the use of metal panels, which can be recycled at the end of their life cycle, thereby minimizing environmental impact.

In this comprehensive guide, we will explore the various factors to consider when choosing metal panels for your project, from material options and finishes to cost implications and installation techniques. By making informed decisions, you can leverage the advantages of metal panels to create a stunning and resilient design that meets the demands of modern architecture.

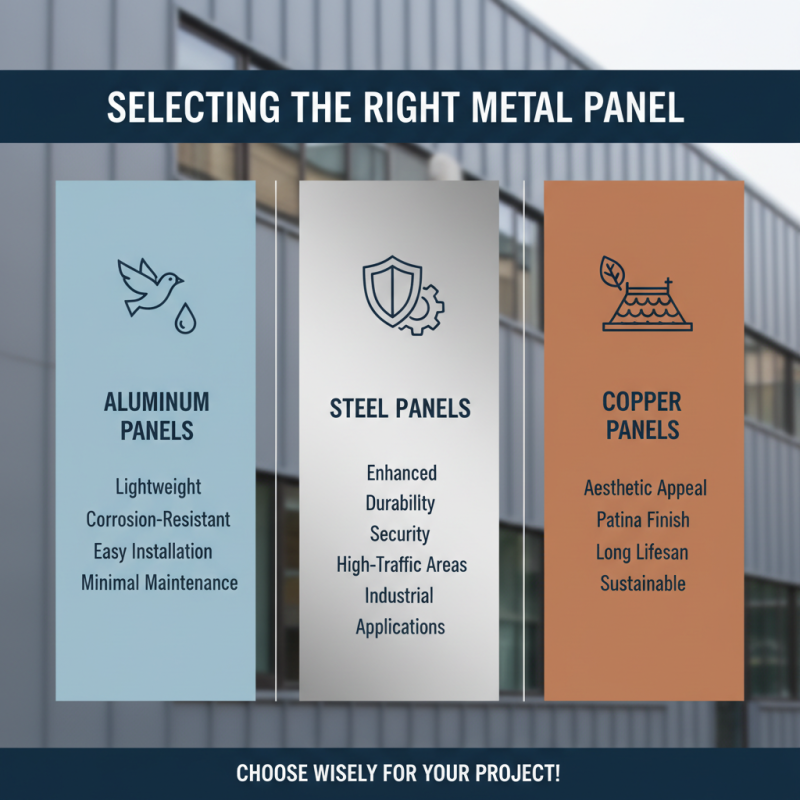

Understanding Different Types of Metal Panels Available in the Market

When selecting the right metal panel for your project, it's essential to understand the different types available in the market. Metal panels come in various materials, including aluminum, steel, and copper, each offering unique benefits. Aluminum panels are lightweight, corrosion-resistant, and perfect for projects requiring easy installation and minimal maintenance. On the other hand, steel panels provide enhanced durability and security, making them suitable for high-traffic areas or industrial applications.

Another critical distinction lies in the design and finish of metal panels. Options range from flat to corrugated, with various coatings that can enhance aesthetics and performance. For example, painted and textured finishes not only improve the visual appeal but also provide added protection against the elements. Additionally, insulated metal panels are gaining popularity for their energy efficiency, combining structural integrity with thermal advantages, ideal for both commercial and residential applications. Understanding these types and their respective features will guide you in making an informed decision that aligns with your project’s specific needs.

Key Factors to Consider When Choosing Metal Panels for Your Project

When choosing metal panels for your project, several key factors come into play to ensure you select the most suitable option. First and foremost, consider the environment where the panels will be installed. Factors such as climate, exposure to moisture, and the potential for corrosion are critical in determining the type of metal and finish you should choose. Stainless steel, for instance, offers excellent corrosion resistance, making it ideal for coastal areas, while galvanized steel is a robust option suitable for various conditions.

Another important factor is the aesthetic appeal of the metal panels. The color, texture, and style of the panels can significantly influence the overall design of your project. Metal panels come in a wide variety of finishes, from sleek and modern to rustic and textured. Think about how the chosen panels will complement the existing architecture and surroundings. It’s also essential to evaluate the thickness and gauge of the metal, as these attributes affect durability and insulation properties.

**Tips:** Always request samples to get a feel for the look and quality of the metal panel before making a purchase. Additionally, consult with professionals to understand the best installation practices and ensure that your choice aligns with building codes and long-term maintenance needs. By keeping these essential factors in mind, you can make a more informed decision that meets both functional and aesthetic requirements.

Ultimate Guide to Choosing the Right Metal Panel for Your Project - Key Factors to Consider

| Panel Type | Material | Typical Applications | Durability | Cost per Square Foot |

|---|---|---|---|---|

| Aluminum Panel | Aluminum | Commercial buildings, facades | High | $3 - $5 |

| Steel Panel | Steel (Galvanized or Coated) | Industrial structures, warehouses | Very High | $2 - $4 |

| Copper Panel | Copper | High-end architecture, roofing | Extreme | $10 - $15 |

| Zinc Panel | Zinc | Architectural applications, facades | High | $6 - $9 |

| Stainless Steel Panel | Stainless Steel | Catering, medical facilities | Very High | $8 - $12 |

Comparing Durability and Maintenance of Various Metal Panel Options

When selecting metal panels for construction or renovation projects, understanding the durability and maintenance of various options is crucial. According to the Metal Construction Association, metal panels can have lifespans exceeding 50 years if properly maintained. However, the maintenance requirements can vary significantly between materials. For instance, galvanized steel chips may require frequent inspections and occasional retouching to prevent rust, while aluminum typically boasts corrosion resistance, reducing the need for intensive upkeep.

Tips: Always consider the environmental exposure of your project location when selecting a metal panel. For areas with high humidity or coastal environments, aluminum or coated steel may be preferable due to their superior resistance to corrosion.

Furthermore, investing in pre-finished panels can reduce long-term maintenance costs. A study by the National Association of Home Builders indicates that homeowners can save up to 30% on maintenance costs over the lifespan of the panels when opting for pre-finished materials. Additionally, the right choice can enhance energy efficiency; insulated metal panels help lower heating and cooling costs, as they provide higher thermal resistance compared to non-insulated alternatives.

Tips: Evaluate the long-term cost benefits by factoring in energy savings alongside initial installation costs. This approach can lead to better financial decisions in the long run, ensuring both durability and cost-effectiveness.

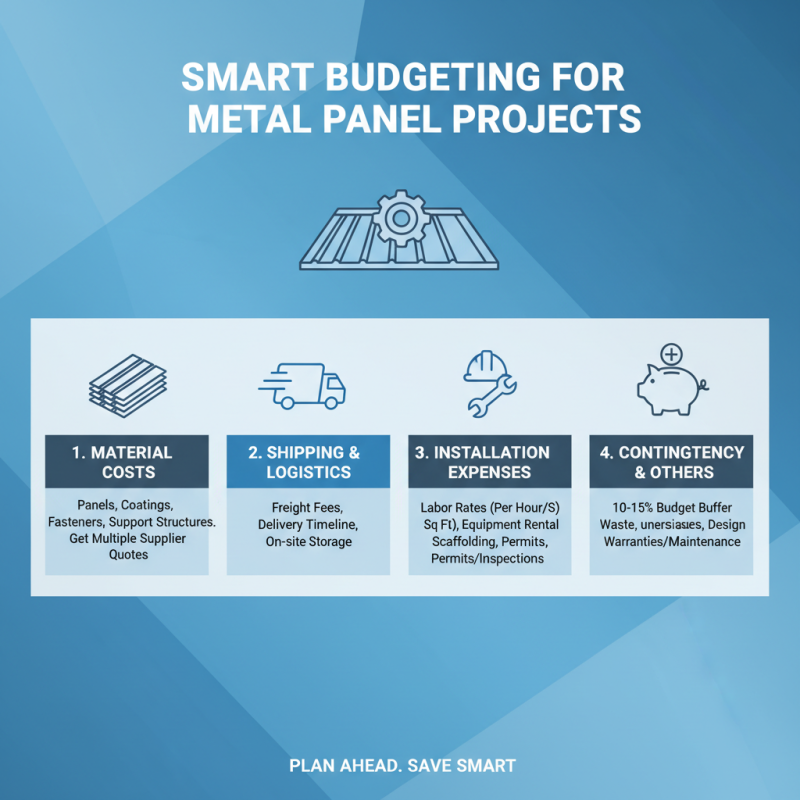

Cost Analysis: Budgeting for Your Metal Panel Project Effectively

When planning a metal panel project, budgeting effectively is crucial to ensure that all aspects are covered without overspending. Begin by conducting a thorough cost analysis of the materials required, including the price of the metal panels, any necessary coatings, and additional hardware such as fasteners and support structures. Gathering multiple quotes from suppliers can help in identifying the most cost-effective options while ensuring quality is not compromised. Additionally, consider the shipping and installation costs that might not be apparent at first glance.

Another important factor in budgeting is anticipating potential upcharges that could arise during the project. This may include the costs associated with custom panel sizes, unexpected site preparation expenses, or modifications required to meet local building codes. Allocating a contingency budget of approximately 10-15% of the total estimated cost can provide a safety net to handle unforeseen expenses while keeping the project on track. By meticulously analyzing these components, you can develop a realistic financial plan that allows for a successful metal panel installation within your desired budget constraints.

Design Aesthetics: Choosing the Right Finish and Color for Metal Panels

When selecting the finish and color for metal panels, design aesthetics play a crucial role in harmonizing with the overall vision of your project. The right finish not only enhances the visual appeal but also affects durability and maintenance over time. For instance, a matte finish can create a sophisticated look, reducing glare and adding depth, while a glossy finish may reflect light and bring a contemporary edge. Understanding the environment in which your panels will be used is also critical; some finishes can be better suited for harsh weather conditions, while others may perform optimally in milder climates.

Color selection is equally important, as it can significantly influence the perception of space. Lighter colors can open up an area, creating an illusion of spaciousness, whereas darker shades may instill a sense of warmth and coziness. Moreover, color can evoke emotions and set the tone of a project; for instance, earthy tones often promote tranquility, while vibrant hues can energize a setting. When selecting your metal panel’s color palette, consider how it interacts with surrounding materials and the natural light in the area, ensuring that your choice not only aligns with aesthetic goals but also enhances the overall functionality and ambiance of the project.

Related Posts

-

2025 How to Choose the Right Exterior Sheathing for Your Home

-

2025 Top Trends in Light Gauge Metal Framing: Key Benefits and Innovations

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance

-

How to Successfully Install Solar Panels: A Step-by-Step Guide

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability

-

How to Choose Cold Formed Metal Framing for Your Construction Project