Why Is Steel Metal Essential in Construction and Manufacturing Industries?

Steel metal plays a pivotal role in construction and manufacturing. Its strength and flexibility make it a preferred choice for builders and manufacturers alike. Expert Daniel Lee, a well-respected figure in the steel industry, once said, "Steel metal is the backbone of modern infrastructure." His insight highlights the material's vital importance.

In construction, steel metal supports heavy structures and offers durability. Skyscrapers and bridges depend on steel for their integrity and longevity. The use of steel metal in these projects ensures they withstand time and environmental changes. However, the industry faces challenges. Recycling and environmental impacts of steel production are pressing concerns that need to be addressed.

Manufacturing also relies heavily on steel metal. It is essential for creating machinery, tools, and vehicles. While innovation drives progress, the reliance on steel must consider sustainability. Efforts to minimize waste and improve recycling processes are crucial. The future of steel metal is bright, but it requires continuous reflection and adaptation.

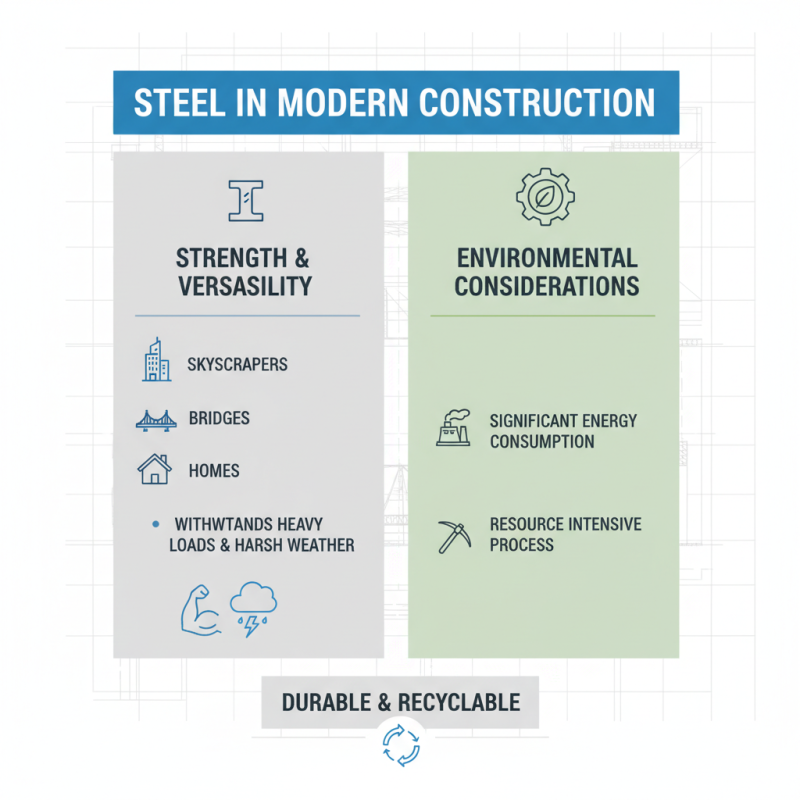

The Role of Steel in Modern Construction: An Industry Overview

Steel plays a vital role in modern construction. It is strong, durable, and versatile. Steel beams are used in skyscrapers, bridges, and homes. They can withstand heavy loads and harsh weather. This makes them a favorite among architects and builders. However, the production of steel has environmental impacts. It requires significant energy and resources.

Another aspect to consider is the lifecycle of steel. It is a recyclable material, which can lessen its impact. Reusing steel reduces waste and conserves resources. Many structures incorporate recycled steel. This makes construction more sustainable. Yet, the process isn’t perfect. Not all steel is recycled effectively, and some still ends up in landfills.

In addition, the cost of steel can fluctuate. This affects project budgets and timelines. Builders may face challenges in sourcing steel at a consistent price. This can lead to delays and increased project costs. It’s essential for the industry to find solutions. Balancing cost, sustainability, and performance is key for the future.

Key Properties of Steel: Strength, Durability, and Versatility Explained

Steel is a vital material in construction and manufacturing. Its key properties include strength, durability, and versatility. These traits make steel suitable for various applications. Builders trust it for creating robust structures. Steel frames can support heavy loads while remaining lightweight. They are essential in skyscrapers and bridges.

Durability is another reason for steel's widespread use. Steel resists corrosion when properly treated. This characteristic extends the lifespan of buildings and machinery. Even in harsh environments, steel can perform well. However, maintenance remains crucial. Neglecting it may lead to rust and wear.

Versatility allows steel to adapt to many designs. It can be molded into various shapes and sizes. This property facilitates creativity in architectural design. Yet, using steel in every situation isn't always ideal. Some projects may benefit from alternative materials. Evaluating each project's needs is imperative.

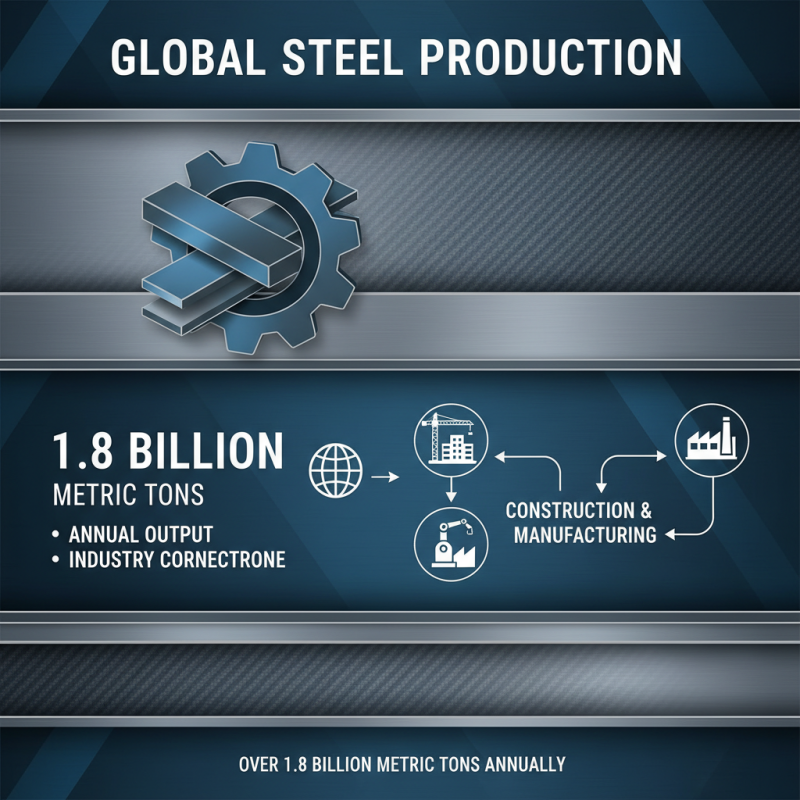

Global Steel Production Statistics and Their Impact on Manufacturing

Steel is a cornerstone in construction and manufacturing. Its production statistics showcase its significance globally. As of recent years, the world produces over 1.8 billion metric tons of steel annually. This massive output highlights steel's role in various industries.

China leads in steel production, contributing nearly half of the global total. However, this dominance raises concerns. The environmental impact of such high output is concerning. Pollution and resource depletion are real risks. Many countries are now advocating for sustainable practices in the steel industry.

In manufacturing, steel plays a crucial role. It is used in everything from cars to skyscrapers. Its durability and versatility are unmatched. Yet, the reliance on steel can be problematic. Dependence on non-renewable resources is a challenge. Innovation is needed to address these issues while meeting global demand.

Cost-Effectiveness of Steel in Large-Scale Construction Projects

Steel is a cornerstone in large-scale construction due to its cost-effectiveness. When comparing materials, steel often emerges as the budget-friendly option. Its high strength-to-weight ratio allows for lighter structures, reducing the need for extensive foundations. This directly saves costs in excavation and labor, making the project more feasible.

Tip: Always calculate the long-term savings of steel use. It often pays off during maintenance periods. While steel can be more expensive upfront, its durability can lower costs in the long run.

Additionally, steel allows for quicker assembly. This leads to reduced labor costs and faster project completion times. However, fluctuations in raw material prices can affect budgets. It's essential to monitor market trends closely.

Tip: Consider alternative steel sources to mitigate price shocks. Exploring recycled steel can also offer cost benefits. Balancing quality with budget is vital, and not all steel options are equal. Reflecting on these choices is crucial for successful project management.

Cost-Effectiveness of Steel in Large-Scale Construction Projects

Sustainability in Steel Production: Recycling and Environmental Impact

Steel production has significant environmental implications. According to the World Steel Association, the industry contributes about 7% of global carbon dioxide emissions. While the demand for steel rises, its environmental impact cannot be overlooked. Many producers are now exploring more sustainable practices, but progress varies widely across regions.

Recycling steel is one effective solution. The American Iron and Steel Institute reports that recycling one ton of steel saves 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone. This recycling process can reduce greenhouse gas emissions by approximately 58%. However, not all steel making results in high recycling rates. Some facilities still rely heavily on virgin materials, neglecting the potential benefits of recycled resources.

The transition to sustainable steel production can be slow. Many producers face economic and technical challenges. Some still utilize outdated methods that are less eco-friendly. The gap between emerging technologies and traditional practices raises questions. Steel's essential role in construction and manufacturing can lead to both progress and setbacks in sustainability efforts. Tracking these movements is crucial for a greener future.

Related Posts

-

Top Innovations in Steel Metal for 2025 Sustainable Construction and Design

-

2025 Top 10 Innovative Steel Metal Products Redefining Industry Standards

-

2025 Top 10 Panel Installation Trends You Need to Know for Your Home

-

Top Benefits of Using Steel Posts for Fencing and Construction Projects

-

Why Choose Light Steel Framing for Your Next Construction Project

-

Ultimate Guide to Choosing the Right Metal Panel for Your Project