2025 Top Trends in Light Gauge Metal Framing: Key Benefits and Innovations

As the construction industry continues to evolve, the methodologies and materials used in building infrastructure are experiencing significant transformations. Among the innovative solutions that are gaining traction, light gauge metal framing stands out for its versatility, efficiency, and sustainability. This construction technique, which employs thin sheets of steel, offers numerous advantages over traditional framing materials, such as wood. With its lightweight nature, light gauge metal framing allows for quicker construction timelines and greater design flexibility, while also providing enhanced durability and resistance to environmental factors.

In 2025, several key trends are expected to shape the future of light gauge metal framing. These trends reflect not only advancements in technology but also a growing emphasis on energy efficiency and sustainability in building practices. As architects and builders increasingly prioritize eco-friendly solutions, innovations in light gauge metal framing are positioning it as a leading choice for modern construction projects. This article delves into the top trends of 2025 in light gauge metal framing, highlighting the critical benefits and innovations that are driving its adoption within the industry. By understanding these trends, stakeholders can better position themselves to harness the full potential of this emerging construction method.

Overview of Light Gauge Metal Framing Technology and Applications

Light gauge metal framing (LGMF) has emerged as a leading alternative to traditional wood framing in various construction applications.

This technology involves the use of thin sheets of steel to create structural frames for buildings.

The inherent strength and durability of metal make it ideal for a wide range of construction methods, including residential, commercial, and industrial projects.

The lightweight nature of the framing system facilitates easier handling, transportation, and installation, significantly reducing labor costs and construction timelines.

In addition to its practical advantages, light gauge metal framing technology is increasingly recognized for its sustainability.

Metal can be recycled multiple times without degrading, reducing waste and promoting eco-friendly building practices.

Advances in manufacturing have led to innovations such as pre-fabricated wall panels and modular systems, which come with pre-attached plumbing and electrical components.

These innovations enhance the efficiency of the construction process while ensuring high-quality, resilient structures that meet modern building standards.

The versatility of LGMF makes it an excellent choice for architects and builders aiming to integrate functionality with sustainability in their projects.

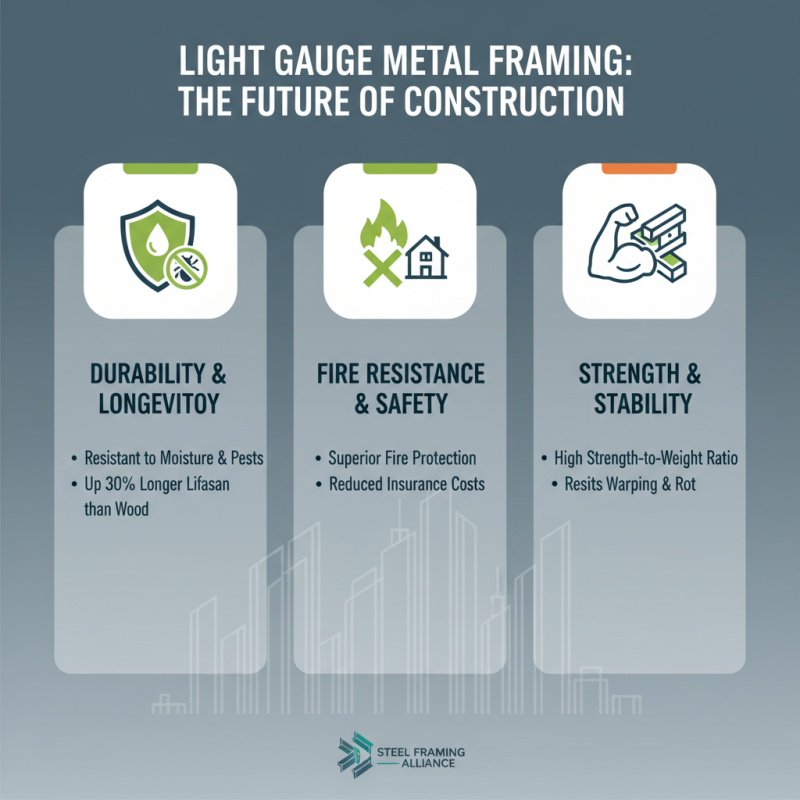

Key Benefits of Using Light Gauge Metal Framing in Construction

Light gauge metal framing has emerged as a pivotal choice in modern construction, offering a myriad of benefits that enhance both efficiency and sustainability. One of the primary advantages is its lightweight nature, which allows for easier handling and installation compared to traditional framing materials. This not only reduces labor costs but also expedites the construction timeline, enabling projects to be completed more swiftly.

Additionally, light gauge metal framing boasts remarkable durability and resistance to environmental challenges such as moisture, termites, and rot. This longevity not only minimizes maintenance costs over time but also contributes to the overall sustainability of a building. By choosing metal framing, builders can ensure a structure that withstands the test of time while providing a safe and healthy environment for occupants.

Tips: When selecting light gauge metal framing for your project, consider the specific environmental conditions and structural requirements of your location. Always work with experienced professionals who understand the nuances of metal framing to maximize its potential benefits. Additionally, staying informed about the latest innovations in metal framing technology can further enhance the efficiency and quality of your construction projects.

Innovations Driving the Future of Light Gauge Metal Framing

Innovations in light gauge metal framing are revolutionizing the construction industry, offering enhanced efficiency and sustainability. One of the most significant trends is the integration of advanced manufacturing technologies, such as robotics and automation, which streamline the production process. These technologies not only reduce labor costs but also improve precision and minimize waste, facilitating a more environmentally friendly approach to construction. Moreover, the adoption of Building Information Modeling (BIM) allows for better planning and coordination among all stakeholders, leading to more effective project delivery.

Another critical innovation is the development of high-performance materials that can withstand extreme weather conditions while maintaining structural integrity. These materials provide greater durability and longevity, reducing maintenance needs and overall project costs in the long run. Additionally, the use of lightweight, high-strength metal enables faster assembly on-site, further reducing labor costs and construction timelines. With these advancements, light gauge metal framing is becoming an increasingly attractive option for architects and builders seeking to create efficient, sustainable, and resilient buildings that meet modern standards.

Sustainability Factors in Light Gauge Metal Framing Practices

The growing emphasis on sustainability in construction has positioned light gauge metal framing as a pivotal solution for reducing environmental impact. According to a report by the Steel Recycling Institute, steel is one of the most recycled materials globally, with approximately 88% of steel products being recycled at the end of their life cycle. This not only minimizes waste but also requires less energy compared to producing new steel. The integration of recycled content in light gauge metal framing significantly enhances the sustainability profile of this construction method, allowing builders to contribute to a circular economy.

Moreover, advancements in manufacturing techniques are introducing innovative practices that further improve the sustainability of light gauge metal framing. Recent studies indicate that modern framing systems can reduce thermal bridging, enhance energy efficiency, and lower the overall carbon footprint of buildings. For instance, according to the American Institute of Steel Construction, using insulated metal panels can decrease energy consumption in structures by up to 40%, promoting long-term savings and environmental benefits. With architects increasingly prioritizing sustainable solutions, the continuous evolution of light gauge metal framing practices reflects a commitment to not only meet current building codes but also to pioneer eco-friendly construction methodologies.

Comparative Analysis: Light Gauge Metal Framing vs Traditional Framing Methods

Light gauge metal framing (LGMF) is gaining traction in the construction industry, offering several advantages over traditional wood framing methods. One of the primary benefits is its durability and resistance to environmental factors such as moisture and pests. According to a report by the Steel Framing Alliance, buildings constructed with light gauge metal framing can exhibit a lifespan that exceeds that of conventional wooden structures by up to 30%. Additionally, LGMF offers superior fire resistance, which can reduce insurance costs and improve overall building safety.

Another consideration is cost-effectiveness. A comparative study conducted by the American Iron and Steel Institute highlights that light gauge metal framing can reduce labor costs by approximately 10-15% due to its lightweight nature, which facilitates easier handling and faster installation. This results in accelerated project timelines, allowing construction companies to complete projects ahead of schedule.

**Tips:** When opting for light gauge metal framing, ensure that your team is trained in proper installation techniques to maximize the framing's benefits. Additionally, always consider local building codes, as they may influence the choice of materials and framing methods. Understanding the environmental impact can also help ensure compliance with sustainable building practices, ultimately leading to a more successful project outcome.

Related Posts

-

Why Cold Formed Metal Framing is the Future of Sustainable Construction Solutions

-

How to Choose Cold Formed Metal Framing for Your Construction Project

-

How to Choose the Best Composite Deck Joists for Long-lasting Durability and Performance

-

What is Steel Framing and How It Transforms Construction Efficiency and Durability

-

2025 How to Choose the Right Exterior Sheathing for Your Home

-

What are Panel Systems? Benefits, Types, and Uses Explained!